Published

Last 1 week

Last 30 days

Latest 24 hours

Profession

Industry

Published

Profession

Industry

Seniority

43

jobs

ICS Outsourcing Nigeria Limited

Lagos, Nigeria

ICS Outsourcing Nigeria Limited

Lagos, Nigeria

ICS Outsourcing Nigeria Limited

Lagos, Nigeria

ICS Outsourcing Nigeria Limited

Abuja, Nigeria

ICS Outsourcing Nigeria Limited

Abuja, Nigeria

ICS Outsourcing Nigeria Limited

Lagos, Nigeria

ICS Outsourcing Nigeria Limited

Lagos, Nigeria

ICS Outsourcing Nigeria Limited

Abuja, Nigeria

ICS Outsourcing Nigeria Limited

Lagos, Nigeria

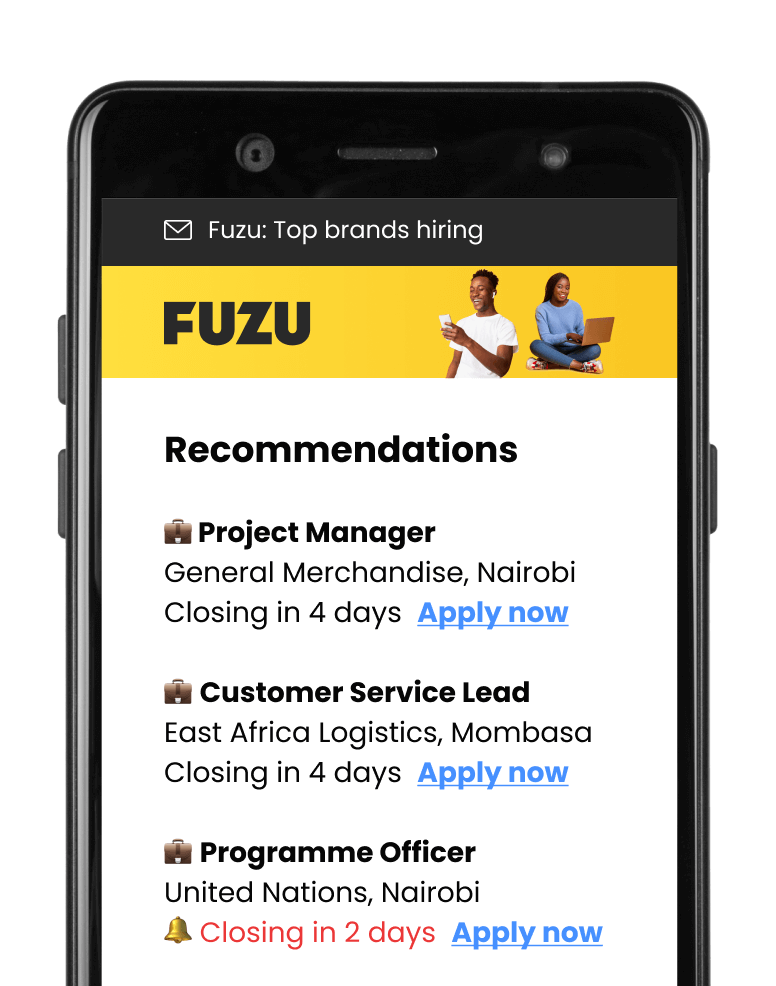

Get personalised job alerts directly to your inbox!

ICS Outsourcing Nigeria Limited

Lagos, Nigeria

Closing: May 4, 2024

8 days remainingPublished: Apr 19, 2024 (7 days ago)

Education:

Work experience:

Language skills:

Contract Type:

Sign up to view job details.

Program Development:

Tool Selection and Setup new Tools Parameters:

Machine Operations:

Quality Control:

Documentation:

Collaboration:

Safety and Compliance:

Continuous Improvement:

Applications submitted via Fuzu have 32% higher chance of getting shortlisted.