Closing: May 9, 2024

10 days remainingPublished: Apr 15, 2024 (15 days ago)

Job Requirements

Education:

Work experience:

Language skills:

Job Summary

Contract Type:

Sign up to view job details.

- The Rig Maintenance Coordinator must be a professional with deep experience in rig mechanical and electrical components and functions,

- He would also be responsible for managing and coordinating maintenance activities on the rig.

- His primary focus would be to reactivate a rig and ensure that all equipment and machinery on same rig are properly maintained to prevent breakdowns, minimize downtime, and enhance safety.

Responsibilities

- The Rig Maintenance Coordinator must be a professional with deep experience in rig mechanical and electrical components and functions,

- He would also be responsible for managing and coordinating maintenance activities on the rig.

- His primary focus would be to reactivate a rig and ensure that all equipment and machinery on same rig are properly maintained to prevent breakdowns, minimize downtime, and enhance safety.

- Maintenance scheduling: They develop and implement maintenance schedules for various equipment and machinery on the rig, including drilling equipment, pumps, generators, and other critical systems.

- Asset management: They oversee the inventory of spare parts and equipment needed for maintenance and repair tasks, ensuring that the rig has adequate supplies to support ongoing operations.

- Coordination: Rig Maintenance Coordinators work closely with rig managers, drilling engineers, and maintenance technicians to coordinate maintenance activities, prioritize tasks, and allocate resources effectively.

- Compliance: They ensure that maintenance activities comply with relevant regulations, industry standards, and company policies to maintain safety and regulatory compliance.

- Performance monitoring: Rig Maintenance Coordinators monitor the performance of equipment and machinery, analysing data and metrics to identify areas for improvement and optimize maintenance strategies.

- Budgeting and cost control: They participate in budget planning and cost control measures related to maintenance activities, ensuring that expenditures are managed efficiently while maintaining operational effectiveness.

- Overall, the Rig Maintenance Coordinator would play a critical role in ensuring the reliability, safety, and efficiency of equipment and machinery, contributing to the overall success of drilling operations.

- He must possess strong.organizational, communication, and technical skills to effectively manage maintenance activities in a challenging offshore environment.

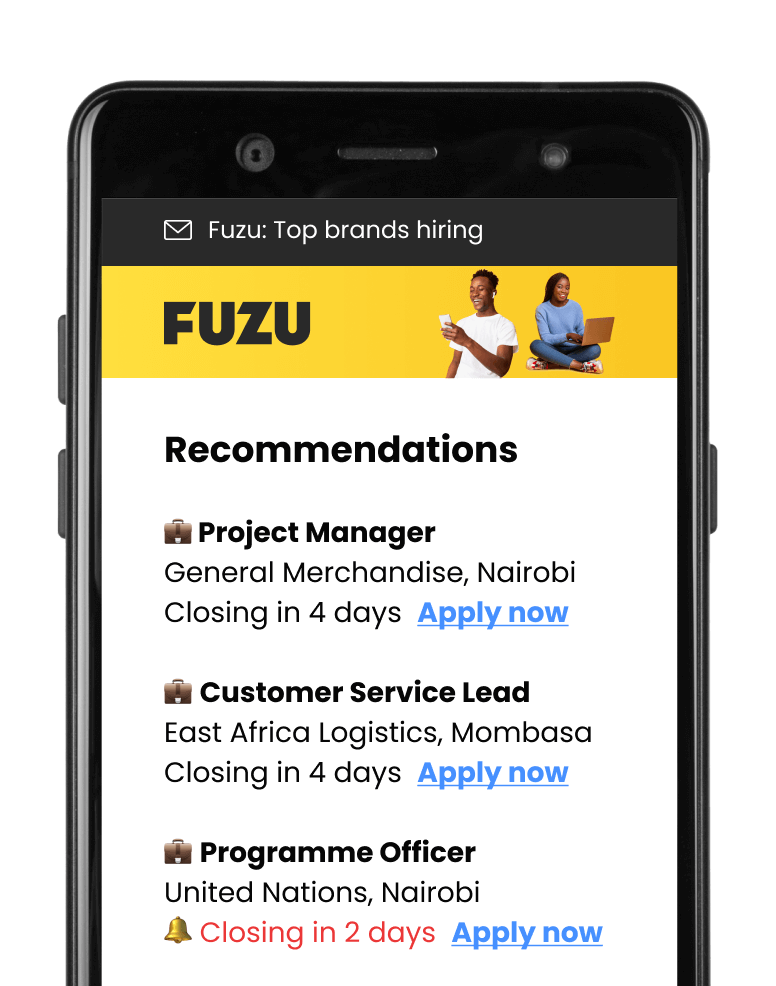

Applications submitted via Fuzu have 32% higher chance of getting shortlisted.