Published

Profession

Industry

Seniority

Published

Profession

Industry

Seniority

1

jobs

Flour Mill of Nigeria Plc

Ibadan, Nigeria

Get personalised job alerts directly to your inbox!

Global Profilers

CLOSEDIbadan, Nigeria

Closing: Aug 6, 2024

10 days remainingPublished: Jul 22, 2024 (5 days ago)

Education:

Work experience:

Language skills:

Contract Type:

Sign up to view job details.

Experience:

The Person Must:

Experience:

The Person Must:

The Job

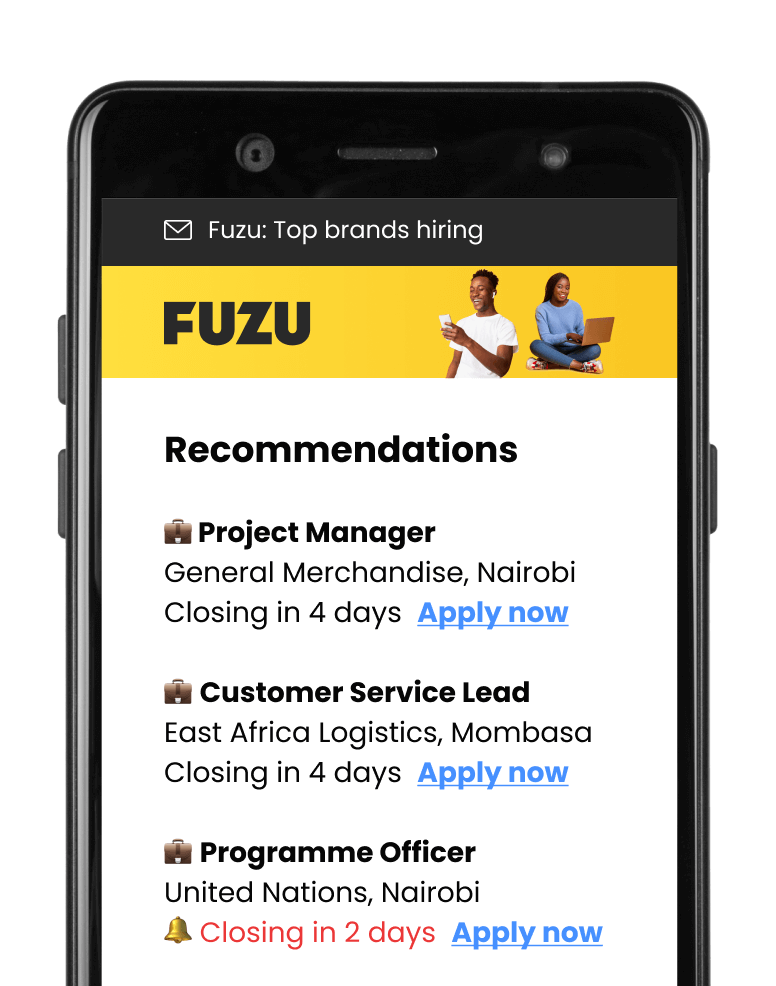

Applications submitted via Fuzu have 32% higher chance of getting shortlisted.