Closing: May 4, 2024

2 days remainingPublished: Apr 19, 2024 (13 days ago)

Job Requirements

Education:

Work experience:

Language skills:

Job Summary

Contract Type:

Sign up to view job details.

- Candidates should possess HND / Bachelor's Degrees with 5 - 10 years relevant work experience.

- Proven experience as a CNC Programmer, preferably with expertise in programming Biesse CNC machines ( Rover A, ATS, 4.55 / Sector 470/Roxyl 5.5)

- Proficiency in CAM software and programming languages used in CNC machining

- Strong knowledge of machining processes, tooling, and materials.

- Attention to detail and the ability to troubleshoot and debug CNC programs.

- Excellent communication and collaboration skills.

- Understanding of safety protocols and compliance requirements in a manufacturing environment.

Responsibilities

- Candidates should possess HND / Bachelor's Degrees with 5 - 10 years relevant work experience.

- Proven experience as a CNC Programmer, preferably with expertise in programming Biesse CNC machines ( Rover A, ATS, 4.55 / Sector 470/Roxyl 5.5)

- Proficiency in CAM software and programming languages used in CNC machining

- Strong knowledge of machining processes, tooling, and materials.

- Attention to detail and the ability to troubleshoot and debug CNC programs.

- Excellent communication and collaboration skills.

- Understanding of safety protocols and compliance requirements in a manufacturing environment.

Program Development:

- Develop CNC programs for Biesse Rover machines based on engineering drawings, specifications, and production requirements

- Utilize CAM (Computer-Aided Manufacturing) software to generate toolpaths and optimize machining processes (Known Pytha 3D Will be added advantage)

Tool Selection and Setup new Tools Parameters:

- Select appropriate tools for specific machining operations.

- Set up and configure tooling on Biesse machines, ensuring proper tool changes and offsets

Machine Operations:

- Operate Biesse Sector, Rover and Roxyl machines to verify and optimize the CNC programs and settings.

- Monitor machine performance and make adjustments as necessary to ensure quality and efficiency.

Quality Control:

- Perform quality checks on machined parts to ensure they meet design specifications and quality standards.

- Troubleshoot and rectify any issues related to the CNC programming or machining process.

Documentation:

- Create and maintain accurate documentation of CNC programs, tooling setups, and machining parameters making folders with Project names.

- Keep records of changes made to CNC programs and update documentation accordingly.

- Preparation of cutting list with BOM of the product.

Collaboration:

- Work closely with Local Nationalities, machinists, and other production team members to optimize manufacturing processes and resolve any issues.

- Provide technical support and guidance to machine operators and Line Supervisors.

Safety and Compliance:

- Adhere to safety guidelines and ensure that all machining activities comply with industry regulations and company policies.

- Participate in safety training programs and promote a safe working environment.

Continuous Improvement:

- Identify opportunities for process improvement and efficiency gains in CNC programming and machining.(i.e. Using Half cuts to create value added items)

- Stay updated on the latest Biesse machine technology and incorporate new techniques and tools into programming practices.

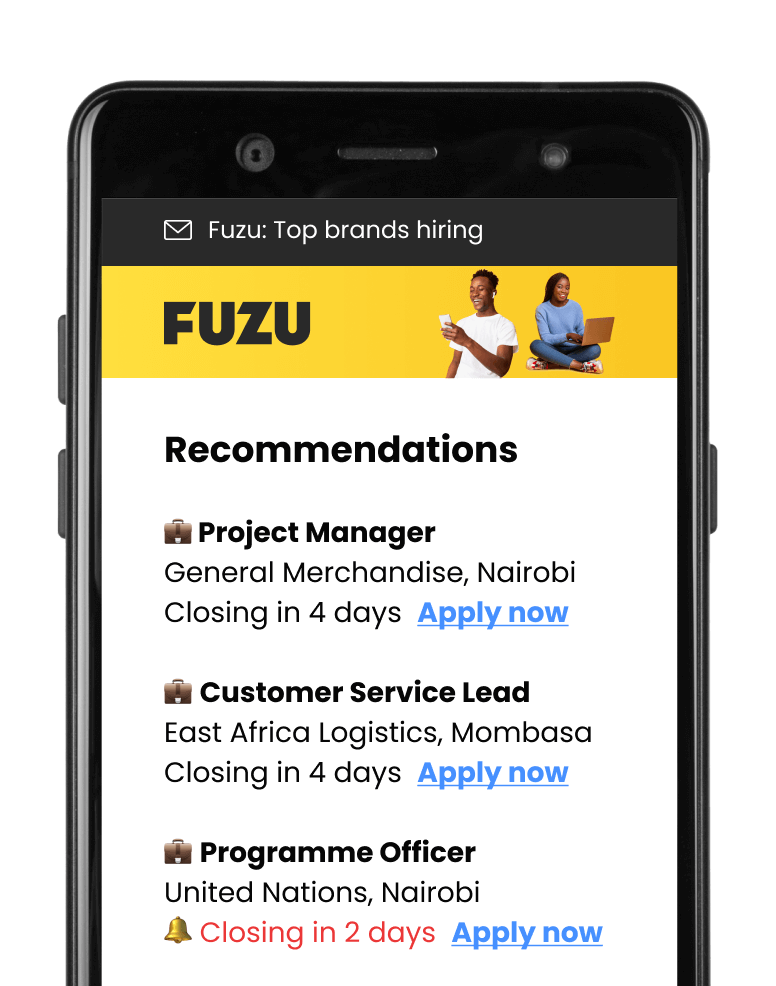

Applications submitted via Fuzu have 32% higher chance of getting shortlisted.