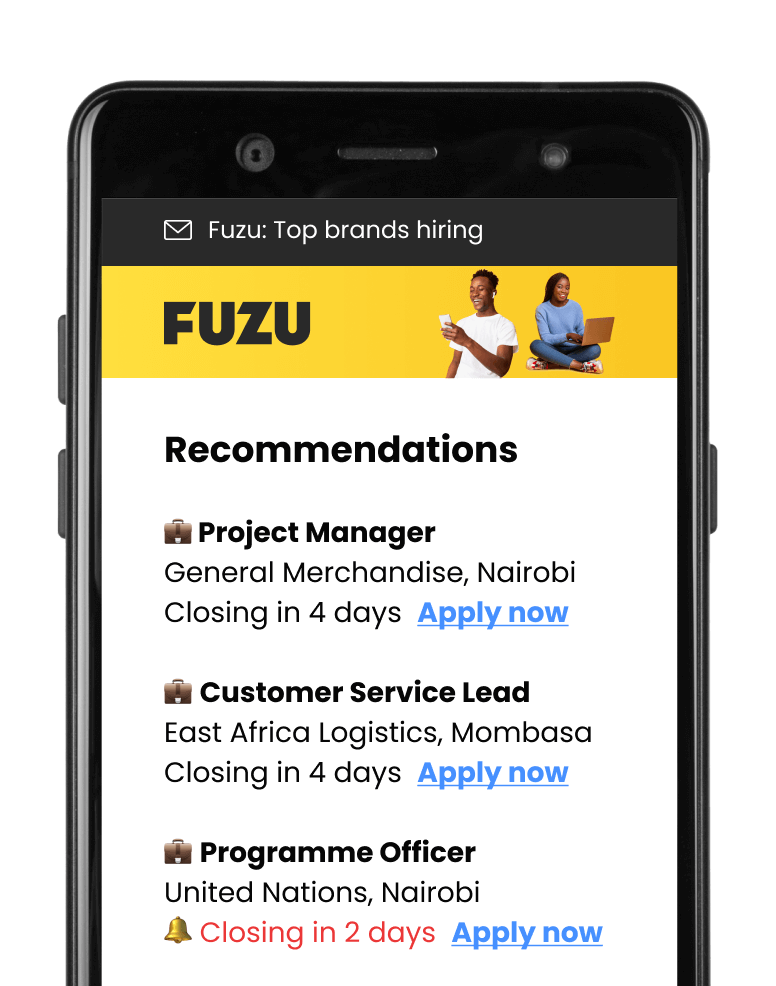

Jobs in NigeriaJobs in KenyaJobs in UgandaJobs in Lagos NigeriaJobs in Abuja NigeriaJobs in Kano NigeriaJobs in Portharcourt NigeriaJobs in Ibadan NigeriaJobs in Enugu NigeriaJobs in Benin City NigeriaJobs in Maiduguri NigeriaJobs in Onitsha NigeriaJobs in Warri NigeriaJobs in Lokoja NigeriaJobs in Abeokuta NigeriaJobs in Nairobi KenyaJobs in Mombasa KenyaJobs in Nyeri KenyaJobs in Naivasha KenyaJobs in Marsabit KenyaJobs in Garissa KenyaJobs in Eldoret KenyaJobs in Kampala UgandaJobs in Mbarara UgandaJobs in Entebbe Uganda

Published

Last 1 week

Last 30 days

Latest 24 hours

Profession

Industry