Published

Last 1 week

Last 30 days

Latest 24 hours

Published

Profession

Industry

Seniority

1

jobs

Nile Breweries

Jinja, Uganda

Uganda National Institute of Public Health

CLOSEDJinja, Uganda

Liberty Uganda

CLOSEDJinja, Uganda

Cycling out of Poverty (CooP-Africa)

CLOSEDJinja, Uganda

3D Services Limited

CLOSEDJinja, Uganda

Nile Breweries

CLOSEDJinja, Uganda

Fiber Foods

CLOSEDJinja, Uganda

MM Integrated Steel Mills (U)

CLOSEDJinja, Uganda

Restless Development

CLOSEDJinja, Uganda

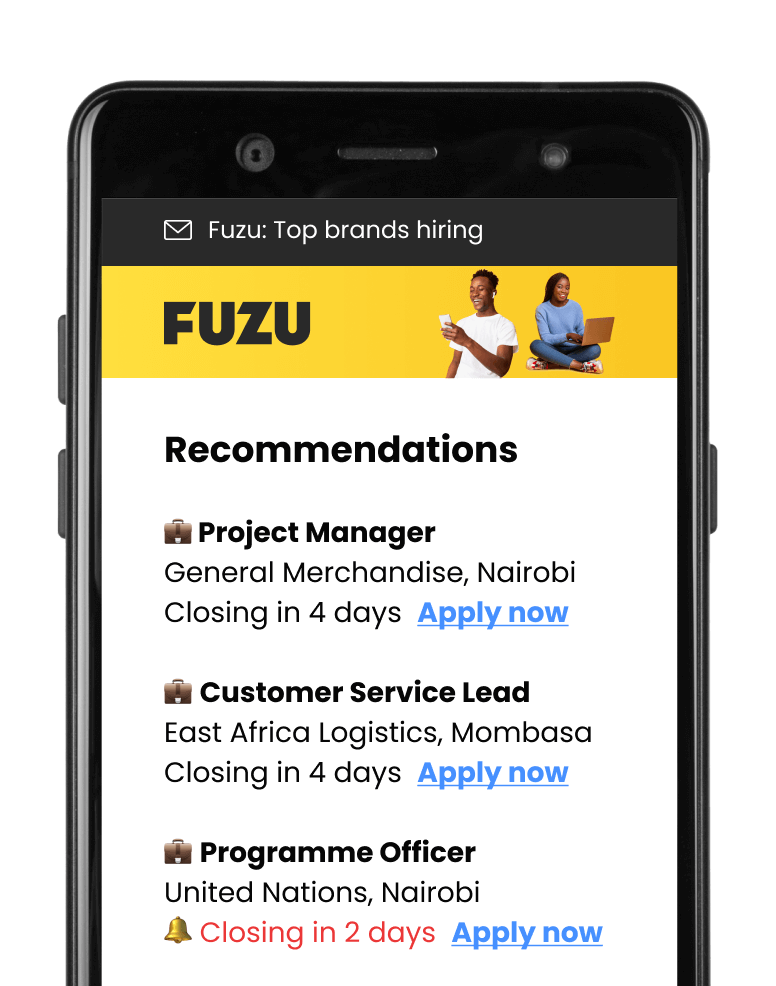

Get personalised job alerts directly to your inbox!

Heifer International

CLOSEDJinja, Uganda

Closing: Apr 26, 2024

3 days remainingPublished: Apr 18, 2024 (6 days ago)

Education:

Work experience:

Language skills:

Contract Type:

Sign up to view job details.

Requirements

• Minimum Diploma in Mechanical/Electrical engineering

• Min – 3 - 5 years in a packaging bottling production environment.

• Experience: 1-3 Years technical mechanical/electrical and bottling experience in a FMCG environment.

Requirements

• Minimum Diploma in Mechanical/Electrical engineering

• Min – 3 - 5 years in a packaging bottling production environment.

• Experience: 1-3 Years technical mechanical/electrical and bottling experience in a FMCG environment.

Operational support

• Provide specialist support to the shift-based teams during operations.

• Assist as functional expert in problem solving.

• This must be undertaken in support of the Process Artisan Where requested, provide guidance and advice to the shift-based teams on mechanical equipment, mechanical faultfinding and correct responses to mechanical failure modes

Planned Maintenance

• Take part in maintenance planning meeting, contributing suggestions and clarifying work required

• Carry out work during the planned maintenance window in accordance with the planned maintenance schedule issued by the planner

• Partake in maintenance postmortems to feedback problems, opportunities and learnings from maintenance activities

Routine Maintenance

• Partake in cleaning, lubrication and inspection in accordance with the maintenance schedule issued by the Maintenance Planner

• Carry out routine maintenance activities in accordance with the maintenance schedules

• Where problems have been uncovered during routine maintenance, these must be resolved using the appropriate problem-solving techniques.

Running Repairs

• On request, partake in carrying out running repairs on plant and equipment, or support the Shift Artisans in carrying out repairs

• When carrying out repairs, assess the problem and determine a course of action

• Complete the administration tasks relating to any running repairs that the Specialist has carried out as per SAP requirements

Problem Solving

• Where problems have occurred during routine activities, apply the correct problem-solving approach to resolve

• Where required, call in additional resources to assist in problem solving or escalate to the Maintenance Controller for direction

• Assist fellow team members to resolve problems on request Take part in ABR's on request

Improvement

• Improve SWI's, SOP's and maintenance tasks on an ongoing basis as issues arise to ensure that the loop is closed out to prevent issues arising.

Housekeeping and Safety

• Always operate in a safe manner, and identify and highlight unsafe work practices so that these may be corrected

• Carry out work according to the work instructions and adhere to appropriate AB InBev policies and procedures

• Carry out house keeping tasks, and apply 5S principles during the execution of duties

Applications submitted via Fuzu have 32% higher chance of getting shortlisted.